A dry vacuum pump for an exceptional juice A Leybold Success Story

December 17, 2024

Alain Milliat Choose Leybold CLAWVAC

LESS WATER & LESS ENERGY FOR THE PERFECT JUICE

If you’ve ever squeezed fresh fruit at home in order to make your own juice, you’ve probably noticed that some fruits, like strawberries or raspberries, generate more “foam” than liquid. On an industrial scale, the juices must be “degassed” (an operation that’s actually more akin to defoaming) in order to allow for bottling.

The Situation

In 2019, at a French food industry trade fair, we met with some representative from the Alain Milliat Company. This company, located in the Drôme, produces “exceptional fruit juices”; an operation on a human scale, which, in the past, was supplied with fruit from the family farm and eventually from local markets. Alain Milliat has successfully positioned itself in the niche market for high-end juices. Distributed in France and booming internationally (particularly in Japan, where its biggest seller is grape juice), the company relies on a network of delicatessens, wine merchants and Relais & Châteaux hotels and gourmet restaurants.

The production workshop, built in 2013 and highly automated, is where all processing of the juices takes places: from washing the fruit to bottling the finished product. Gilles Eparvier, the company’s maintenance manager, with whom we spoke at the show, told us that he’s very satisfied with the production process which meets the high standards of quality and hygiene required for their juices.

The "Water" Challenge

Aware of environmental issues, the Alain Milliat company was looking for a less water intensive vacuum solution for the juice deaerator. The degassing step takes place between the first and second pasteurization stages. A liquid ring pump was used for this operation. This type of pump is inexpensive to purchase, but has a very high cost of ownership in terms of electrical power and water, requiring approximately 1,500m3 of water per year, plus the cost of discharge and reprocessing or several thousand euros spent each year on a single vacuum pump.

The Leybold Solution

Leybold proposed the CLAWVAC to Mr. Eparvier, which is a an oil free air-cooled dry vacuum pump. The rotating Claw mechanism completely eliminates water consumption, and avoids any risk of contaminating the process. The Stainless Steel claws are highly resistant to the corrosion created by high levels of humidity, in addition to the acidity from the fruit. After several months of use, regular monitoring by Leybold teams and complete dismantling for inspection, the pump is working as expected and shows no signs of wear.

It’s built to last!

Giles Eparvier (Maintenance Manager - Alain Milliat) and Pierre Lantheaume (Business Development Manager - Leybold)

CLAWVAC installed on pasteurization system - Alain Millia

What the customer had to say...

Q&A with Gilles Eparvier

Why use a liquid ring pump in this application?

We didn’t really choose to do so; it was already integrated directly into the pasteurization line.

Were you thinking of replacing this pump when you went to the show in 2018?

I had come with some ideas, and replacing this pump was one of them. I was looking for a pump that uses less energy and water, but I never thought I’d be able to completely eliminate the need for water.

Why Leybold?

First of all, for the support and professionalism of Leybold’s staff: they understood our needs and were able to respond to them as quickly as possible. After installing the pump, we were not left on our own, there has been a regular and close follow-up from Leybold people to make sure the pump was performing as expected.

Have you done your calculations? Was it a good investment?

It was indeed an investment, but it’ll pay for itself in less than a year. More importantly, we’ve drastically reduced our water consumption, and we now only use it in operations where it’s really necessary, such as washing the fruit, for example.

Products for food applications

- CLAWVAC

- NOVADRY

- DRYVAC

- SOGEVAC

- SCREWLINE

- VACUBE

- VAControl

- Hygienic Enclosure

CLAWVAC

CLAWVAC

In the most demanding food processes such as mixing or by-product conveying that can have heavy contamination, our CLAWVAC pumps with stainless steel claws are ideal with their on-site chamber cleanability capability.

- Dry claws -> The most robust technology for demanding processes

- Stainless steel claws -> Corrosion free even with high humidity

- Released for MAP with oxygen -> Suitable for red meat packaging with high O2

- Pumping chamber cleanable on-site -> No downtime due to vacuum pumps

- Minimal maintenance requirement -> Low total cost of ownership

NOVADRY

NOVADRY

Our NOVADRY not only improves food safety with its 100% oil-free operation but also provides longer uptime thanks to its robustness over oil sealed pumps in challenging processes such as tumbling or stuffing of meats.

- Dry screw technology -> Very robust in harsh applications

- 100% oil free -> Improved food safety

- Air cooling -> Quick & easy installation

- Minimal maintenance requirement -> Low total cost of ownership

- Released for MAP with oxygen -> Suitable for red meat packaging with high O2

DRYVAC

DRYVAC

Our DRYVAC range is a compact, water-cooled and silent dry screw pump that can be installed in close proximity of your production line, increasing your packaging performance. With a hygienic design, you can washdown our pumps along with your other production equipment.

- Dry screw technology -> Very robust in harsh applications

- Clean vacuum -> Improved food safety

- Extremely compact -> Easy to install on the line

- Very low noise -> Improve working environment

- Low heat emission -> Can be localized to improved machine performance

SOGEVAC

SOGEVAC

Our best in class proven oil sealed rotary vane SOGEVAC pumps have been delivering in several food packaging and processing application thanks to their robustness, stable performance and ease of service over competitive oil sealed pumps.

- Best in class rotary vane pumps -> Proven technology for food applications

- High pumping speed at all pressures -> Improved packaging machines performance

- Low operating temperature -> Longer oil exchange intervals

- States-of-the-art exhaust filtering technology -> Clean vacuum

- Easy maintenance -> Low cost of ownership

SCREWLINE

SCREWLINE

For demanding food applications that required excellent water vapor handling, organic acid tolerance etc., such as food freeze drying, our dry screw air cooled SCREWLINE pump is an excellent fit with its on-site pump chamber cleanability feature.

- Dry screw technology -> Very robust in harsh applications

- Air cooling -> Quick & easy installation

- Pumping chamber cleanable on-site -> No downtime due to vacuum pumps

VACUBE

VACUBE

VACUBE is a new generation of intelligent, oil-sealed screw vacuum pumps with variable speed drive (VSD) technology. VACUBE generates vacuum on demand and provides significant energy savings for a wide range of food applications.

- Variable oil sealed screw pump -> Energy saving solution

- Smart control -> Monitoring of process parameters and pump sensors

- Size up to 4800 m3/h -> The answer to high pumping speed requirements

- Modular concept -> Perfect pump for central vacuum systems

- Energy recovery kit -> Additional energy saving possible

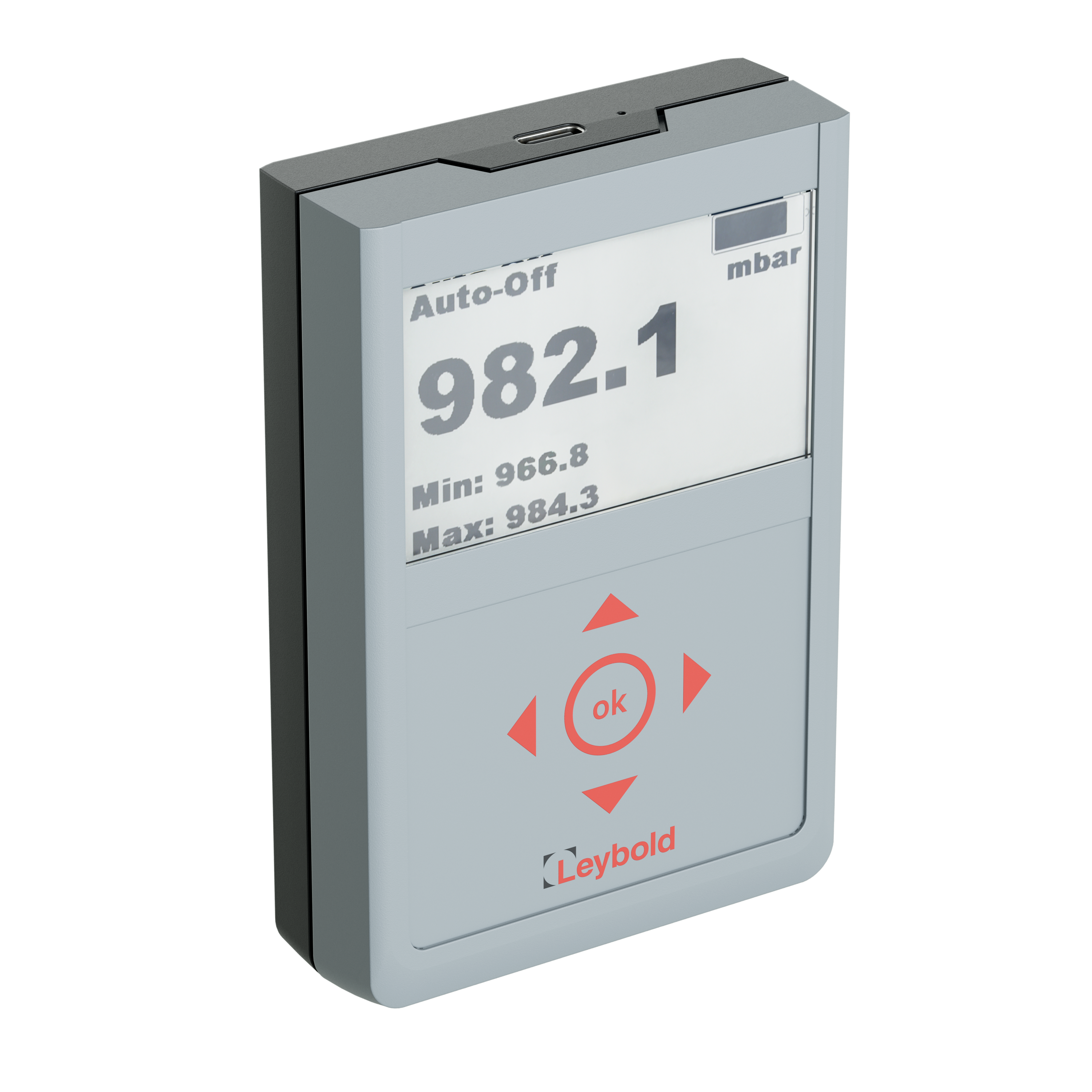

VAControl

VAControl

Leybold goes one step further to offer modern solutions for your central vacuum systems based on industry 4.0 with the VAControl. Control your vacuum pumps, monitor and schedule your process with VAControl’s various user friendly options.

- Allows to control multiple pumps -> Easy to implement

- Pressure set point -> Offer energy saving potential

- Smart control -> Improves products quality by optimal process pressure

Hygienic Enclosure

Hygienic Enclosure

Our range of stainless steel hygienic enclosures, perfectly protects your vacuum pump from water damage during against daily wash-down required on the food industry.

Hygienic enclosures avoid water retention points allowing you to achieve a high level of food safety. Hygienic enclosures are designed for your Leybold pumps to protect during washdown without disrupting your pump's thermal management or performance..

- For washdown environment -> Protect your vacuum pump

- Specifically designed for Leybold pumps -> Ensures optimal cooling

- Installation close to the process -> Increases machine performance

- Delivered as a kit -> Easy to assemble and install

CLAWVAC

In the most demanding food processes such as mixing or by-product conveying that can have heavy contamination, our CLAWVAC pumps with stainless steel claws are ideal with their on-site chamber cleanability capability.

- Dry claws -> The most robust technology for demanding processes

- Stainless steel claws -> Corrosion free even with high humidity

- Released for MAP with oxygen -> Suitable for red meat packaging with high O2

- Pumping chamber cleanable on-site -> No downtime due to vacuum pumps

- Minimal maintenance requirement -> Low total cost of ownership

NOVADRY

Our NOVADRY not only improves food safety with its 100% oil-free operation but also provides longer uptime thanks to its robustness over oil sealed pumps in challenging processes such as tumbling or stuffing of meats.

- Dry screw technology -> Very robust in harsh applications

- 100% oil free -> Improved food safety

- Air cooling -> Quick & easy installation

- Minimal maintenance requirement -> Low total cost of ownership

- Released for MAP with oxygen -> Suitable for red meat packaging with high O2

DRYVAC

Our DRYVAC range is a compact, water-cooled and silent dry screw pump that can be installed in close proximity of your production line, increasing your packaging performance. With a hygienic design, you can washdown our pumps along with your other production equipment.

- Dry screw technology -> Very robust in harsh applications

- Clean vacuum -> Improved food safety

- Extremely compact -> Easy to install on the line

- Very low noise -> Improve working environment

- Low heat emission -> Can be localized to improved machine performance

SOGEVAC

Our best in class proven oil sealed rotary vane SOGEVAC pumps have been delivering in several food packaging and processing application thanks to their robustness, stable performance and ease of service over competitive oil sealed pumps.

- Best in class rotary vane pumps -> Proven technology for food applications

- High pumping speed at all pressures -> Improved packaging machines performance

- Low operating temperature -> Longer oil exchange intervals

- States-of-the-art exhaust filtering technology -> Clean vacuum

- Easy maintenance -> Low cost of ownership

SCREWLINE

For demanding food applications that required excellent water vapor handling, organic acid tolerance etc., such as food freeze drying, our dry screw air cooled SCREWLINE pump is an excellent fit with its on-site pump chamber cleanability feature.

- Dry screw technology -> Very robust in harsh applications

- Air cooling -> Quick & easy installation

- Pumping chamber cleanable on-site -> No downtime due to vacuum pumps

VACUBE

VACUBE is a new generation of intelligent, oil-sealed screw vacuum pumps with variable speed drive (VSD) technology. VACUBE generates vacuum on demand and provides significant energy savings for a wide range of food applications.

- Variable oil sealed screw pump -> Energy saving solution

- Smart control -> Monitoring of process parameters and pump sensors

- Size up to 4800 m3/h -> The answer to high pumping speed requirements

- Modular concept -> Perfect pump for central vacuum systems

- Energy recovery kit -> Additional energy saving possible

VAControl

Leybold goes one step further to offer modern solutions for your central vacuum systems based on industry 4.0 with the VAControl. Control your vacuum pumps, monitor and schedule your process with VAControl’s various user friendly options.

- Allows to control multiple pumps -> Easy to implement

- Pressure set point -> Offer energy saving potential

- Smart control -> Improves products quality by optimal process pressure

Hygienic Enclosure

Our range of stainless steel hygienic enclosures, perfectly protects your vacuum pump from water damage during against daily wash-down required on the food industry.

Hygienic enclosures avoid water retention points allowing you to achieve a high level of food safety. Hygienic enclosures are designed for your Leybold pumps to protect during washdown without disrupting your pump's thermal management or performance..

- For washdown environment -> Protect your vacuum pump

- Specifically designed for Leybold pumps -> Ensures optimal cooling

- Installation close to the process -> Increases machine performance

- Delivered as a kit -> Easy to assemble and install

- Related applications

- Related products

- Documents

.jpg)